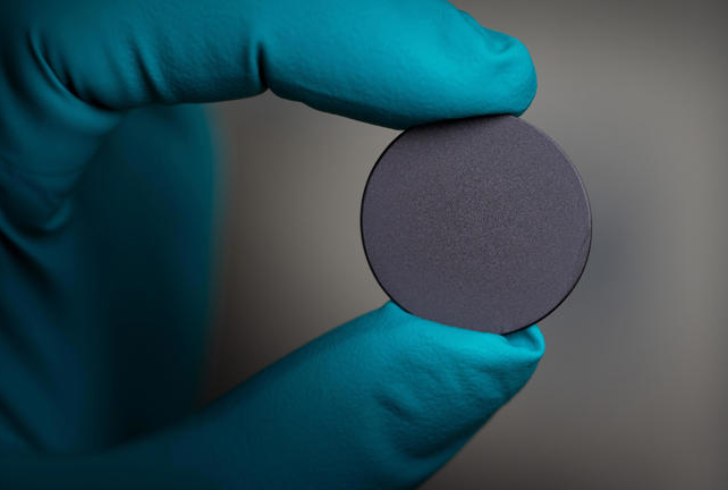

A Cardiff-based company is pushing the boundaries of technology by placing a factory in space. The concept may sound like science fiction, but Space Forge has taken a major step toward making orbital manufacturing a reality. The startup recently launched a microwave-sized factory into orbit and successfully demonstrated that its furnace can reach temperatures around 1,000°C.

The goal is to produce semiconductors in space, which can later be used on Earth in electronics, communications, computing, and transportation systems.

Why Space is Ideal for Semiconductors

Space offers conditions that are hard to replicate on Earth. In a weightless environment, atoms in semiconductor materials align perfectly into a highly ordered 3D structure. The vacuum of space also eliminates the risk of contamination, resulting in purer materials.

According to Josh Western, CEO of Space Forge, “The work that we’re doing now is allowing us to create semiconductors up to 4,000 times purer in space than we can currently make here today.”

Purer semiconductors mean better performance. These materials could power 5G towers, EV chargers, and the latest aircraft, improving efficiency and reliability across various industries.

The First Space-Based Furnace

The company’s mini-factory launched aboard a SpaceX rocket during the summer. Teams at mission control in Cardiff have been monitoring its systems remotely.

Veronica Viera, payload operations lead at Space Forge, described an image sent back from the furnace showing glowing plasma. The plasma, heated to approximately 1,000°C, is a core element of the in-space manufacturing process.

Viera said observing the plasma was “one of the most exciting moments of my life,” highlighting the significance of the demonstration.

Plans for Scaling Up

Space Forge is preparing to construct a larger orbital factory capable of producing material for roughly 10,000 semiconductor chips. A key step involves safely returning the manufactured materials to Earth.

For this purpose, a heat shield named Pridwen, inspired by the legendary shield of King Arthur, will be tested to endure the extreme heat of re-entry. Ensuring the material survives the return journey is essential for practical applications.

In-Space Manufacturing Beyond Semiconductors

Other companies are exploring the potential of space manufacturing for a variety of products, including pharmaceuticals and artificial tissues.

Libby Jackson, head of space at the Science Museum, notes that the field is still in its early stages, with small-scale demonstrations paving the way. She adds, “By proving the technology, it opens the door for products that can be made in space and returned to Earth, providing real benefits for people worldwide.”

Space Forge’s work represents a significant step toward a future where manufacturing is no longer limited to Earth. By leveraging microgravity and the vacuum of space, semiconductors with unmatched purity and performance can be produced.

As the company develops larger factories and tests re-entry technologies, the era of orbital manufacturing moves closer to reality, promising innovations that could impact electronics, transportation, and communication industries globally.